Float-level switches are utilities used to control and monitor the liquid level in transmission and storage facilities or systems. The correct measurement of liquid levels is very important in a transmission apparatus or a storage enclosure. In fuel-storage tanks, for example, there is no way to determine the fuel level except through float-level switches. Read More…

Sierra`s Innova-Switch™ electronic instruments and devices represent the state-of-the-art in gaseous and liquid flow switching or liquid level control.

At Ryan Herco Flow Solutions, we dedicate ourselves to providing advanced fluid handling products and engineered solutions that meet the demands of a wide range of industries. Our focus is on delivering dependable components and systems that support process efficiency, safety, and reliability.

SOR® level switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. All float level switches are individually built with strict attention to detail to meet the exact specifications of your process. Available as float level switches and displacer level switches, our product offering provides superior...

More Float Level Switch Manufacturers

Float-level switches, also known as float switches or liquid level sensors, are vital components used to detect and control liquid levels in a vast range of industrial, commercial, and residential applications. These devices are widely implemented to automate the operation of other equipment—such as pumps, alarms, and valves—whenever a liquid reaches a predetermined high or low point within a tank, well, or vessel. Users and engineers seek float-level switches for their unmatched reliability, cost-effectiveness, and adaptability, making them suitable for monitoring and managing a variety of fluids including water, oil, chemicals, and wastewater.

What is a Float Level Switch? Understanding the Basics

A float-level switch is an electromechanical device that reacts to changes in liquid level by opening or closing an electrical circuit. As the float rises or falls with the liquid, it triggers a switch mechanism—often using a magnet and a reed switch—to send a signal to control systems or directly to external devices. This simple yet highly effective technology is fundamental to liquid level monitoring and automation across multiple industries.

Components of Float Level Switches

To fully understand how float-level switches work and what sets them apart from other liquid level sensors, it is important to examine their core components:

Sensor Component – The primary part of any float-level switch is its sensor. This component detects the presence or absence of liquid at a specific level, activating when the fluid deviates from preset thresholds. Sensors are designed to withstand the chemical, temperature, and pressure conditions of the application environment, ensuring long-term reliability.

Output Signal – Upon activation, the sensor generates an output signal, which can be electrical (such as ON/OFF, NO/NC contacts), analog, or digital. These signals provide critical feedback to programmable logic controllers (PLCs), distributed control systems (DCS), or local alarms, enabling real-time monitoring and process automation. Modern float switches can even interface with industrial IoT systems for remote monitoring and predictive maintenance.

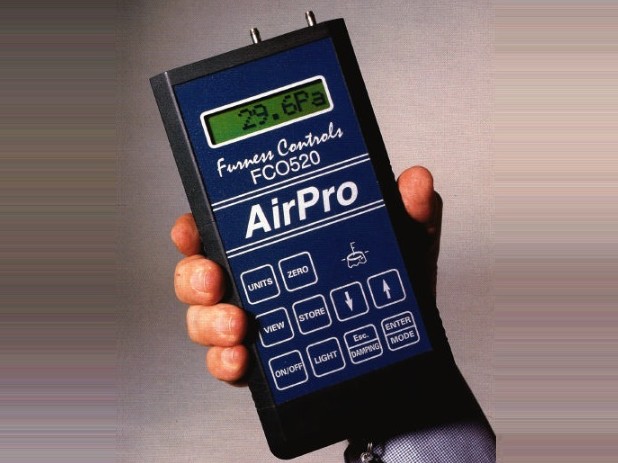

Interface – The interface refers to how the switch communicates information to operators and control systems. Traditional float-level switches feature analog interfaces such as dials or needles for manual setting and readout, while advanced models offer digital displays with numeric readouts, touch controls, and connectivity for integration with SCADA or building management systems. In complex industrial processes, multiple float-level switches may be networked to provide comprehensive liquid level data for distributed systems.

Are you wondering which float-level switch interface best fits your application? Compare analog vs. digital float switch interfaces and discover the key differences in usability, accuracy, and system integration.

How Float Level Switches Function

At their core, float-level switches consist of a hollow float attached to a lever arm or stem, which houses a sensor or switch—most commonly a hermetically sealed reed switch. The float contains a magnet and is engineered to move freely with the liquid surface. When rising or falling liquid levels cause the float to reach a set point, the magnetic field actuates the reed switch, opening or closing an electrical circuit. This triggers a control action, such as starting or stopping a pump, activating an alarm, or shutting off a valve.

Key points on float-level switch operation:

- Activation by buoyancy and gravity—no external power is needed for basic operation

- Provides point-level detection (high or low level) or multi-point level monitoring

- Compatible with a wide range of liquids—water, oils, fuels, chemicals, and more

- Can be configured for fail-safe operation in safety-critical applications

Curious about float switch reliability? Explore how float-level switches maintain accuracy and durability in harsh environments such as chemical storage tanks, wastewater treatment plants, and oil refineries.

Types of Float Level Switches

Float-level switches come in several designs to suit diverse application requirements. Choosing the right type depends on factors such as tank geometry, mounting orientation, liquid properties, and control needs. Here’s an in-depth look at the two most common types:

Stem-Mounted Float Switches

Stem-mounted float switches feature one or more floats attached to a rigid stem or rod, which is installed vertically or horizontally into a tank or vessel. These switches are available as single-point (one float at a fixed level) or multi-point (multiple floats at different levels for sequential control or alarms). The stem constrains the motion of the float, providing precise level detection at designated points. Stem-mounted designs are ideal for confined spaces, narrow tanks, and situations where accurate, repeatable level measurement is critical.

Typical applications for stem-mounted float switches include:

- Boiler water level controls

- Hydraulic reservoir monitoring

- Cooling tower sump management

- Process tank level alarms

Looking for a solution for tight or restricted tank installations? See how stem-mounted float switches deliver reliable level sensing in space-constrained environments.

Cable-Suspended Float Switches

Also known as tethered or suspended float switches, cable-suspended float switches are attached to a flexible cable anchored above the liquid. As the liquid level rises or falls, the float pivots and changes angle, actuating the internal switch at set points. These designs can be simple single-point switches or feature multiple switch points for complex control schemes. Cable-suspended float switches are especially popular in large tanks, sumps, wells, and open water bodies, thanks to their ease of installation and adaptability to varying liquid levels.

Key advantages of cable-suspended float switches include:

- Quick, tool-free installation and repositioning

- Suitable for turbulent or sloshing liquids

- Low maintenance and easy inspection

- Versatility for both clean and dirty water applications

As the switch floats with the water level, it naturally adjusts to changing volumes without becoming stuck or misaligned. For example, in wastewater lift stations, cable-suspended floats provide dependable pump control, minimizing risk of overflow or pump dry-running.

Need help selecting the best float switch for your tank or well? Compare stem-mounted vs. cable-suspended float switches for your specific fluid handling application.

Additional Types and Specialty Float Switches

In addition to the main types described above, there are several specialty float-level switches designed for demanding or unique applications, such as:

- Miniature float switches for laboratory instruments and small containers

- Explosion-proof float switches for hazardous locations (UL, ATEX, IECEx certified)

- Sanitary float switches for food, beverage, and pharmaceutical processing (FDA-compliant materials)

- High-temperature and high-pressure float switches for boilers and process vessels

- Dual-level and triple-level switches for multi-stage pump control or alarming

Want to learn more about float switch technology? Browse an in-depth guide to specialty float-level switches and their applications in challenging environments.

Applications of Float Level Switches

Float-level switches are indispensable in a vast spectrum of industries, supporting automation, process control, safety, and environmental compliance. Here are some of the most common and high-impact applications:

- Aerospace: Hydraulic system monitoring, fuel tank level sensing, coolant reservoir management

- Automotive: Washer fluid tanks, oil reservoir management, HVAC condensate tanks

- Manufacturing: Chemical dosing tanks, process tanks, lubrication systems, machine coolant management

- Mining: Slurry tank monitoring, dewatering pumps, reagent solution tanks

- Medical: Dialysis machines, sterilizer water tanks, pharmaceutical mixing vessels

- Water & Wastewater: Lift station pump control, stormwater overflow prevention, potable water storage monitoring

- Food & Beverage: Ingredient tanks, brewing vessels, cleaning solution tanks, CIP system monitoring

- Oil & Gas: Oil/water separator tanks, brine tanks, fuel storage level management

- Power Generation: Boiler feedwater tanks, cooling system reservoirs, transformer oil monitoring

Are you evaluating float-level switches for your industry? Discover application-specific recommendations for float switch selection and integration.

Benefits of Float Level Switches

Float-level switches offer a compelling array of benefits for liquid level detection and process automation. Here’s why they’re the preferred solution in countless systems:

- Waste Prevention – By automating the control of pumps, valves, and alarms, float-level switches prevent costly overflows, leaks, and spillage. This ensures optimal use of raw materials and protects the environment from hazardous releases.

- Cost Savings – The affordability and low maintenance requirements of float-level switches translate into significant operational savings. Their simple mechanical design reduces downtime and repair costs compared to complex electronic sensors.

- High Reliability and Accuracy – Durable construction and proven technology deliver consistent performance, even in harsh or corrosive environments. Many models are rated for millions of switching cycles, with accuracy sufficient for most industrial and commercial needs.

- Easy Installation and Flexibility – Most float switches can be installed quickly without specialized tools. Their compact design allows integration into virtually any tank, regardless of shape or size—making them ideal for retrofit and OEM projects alike.

- Versatility – Compatible with a wide variety of liquids, including water, oil, chemicals, and slurries. Customizable options are available for challenging applications, such as high temperature, high pressure, or sanitary requirements.

- Precise Switching Sensitivity – Advanced float-level switches offer high sensitivity, enabling detection of very small changes in liquid level. This is critical for applications demanding precise process control or early leak detection.

- Low Power Consumption – Most float-level switches operate passively or require minimal electrical power, making them suitable for remote and off-grid installations.

- Compliance and Safety – Float switches support regulatory compliance in industries such as water treatment, food processing, and hazardous material storage. Fail-safe configurations and redundant systems enhance process safety.

Trying to maximize efficiency in your liquid handling system? Compare float-level switches to alternative level sensors such as ultrasonic, capacitive, or hydrostatic sensors, and see why floats remain the most trusted solution for many applications.

Use Cases: Real-World Examples of Float Level Switches

To better understand the value of float-level switches, let’s consider several real-world scenarios:

- Municipal Water Treatment: Float switches regulate pump operation in lift stations, ensuring continuous removal of wastewater and preventing overflows during heavy rainfall.

- Industrial Chemical Processing: Multi-point float switches manage dosing of acids and bases, providing alarms if levels fall below safe thresholds to protect equipment and personnel.

- Residential Sump Pump Systems: Homeowners rely on cable-suspended float switches to automatically activate sump pumps, protecting basements from flooding during storms.

- Food & Beverage Production: Sanitary float switches help monitor liquid ingredient tanks, ensuring consistent product quality and compliance with health regulations.

- Oil & Gas Storage: Explosion-proof float switches control pumps and alarms in hazardous environments, reducing the risk of spills and improving operational safety.

Looking for case studies or success stories? Read how leading companies optimize operations with float-level switch technology in water, chemical, and oil management.

How to Choose the Right Float Level Switch

Selecting the best float-level switch for your application involves evaluating several key factors:

- Liquid Type: Consider chemical compatibility, temperature, and viscosity. For corrosive or hazardous fluids, choose switches with appropriate wetted materials (e.g., stainless steel, polypropylene, Teflon).

- Tank or Vessel Geometry: Vertical vs. horizontal orientation, available mounting locations, and tank access all impact switch selection.

- Switching Requirements: Decide between single-point or multi-point sensing, as well as NO/NC (normally open/normally closed) contact configuration.

- Environmental Conditions: Assess whether explosion-proof, sanitary, or high-temperature/high-pressure ratings are necessary.

- Integration Needs: Ensure compatibility with existing control systems—consider analog, digital, or networked output signals.

Not sure which float switch model is right for you? Use our interactive float-level switch selector tool to match your application with the ideal product features.

Choosing the Right Float Level Switch Supplier

Working with a reputable, experienced float-level switch supplier is essential for successful project outcomes. Here are important considerations to guide your selection process:

- Industry Expertise: Look for suppliers with proven experience serving your specific industry—be it water treatment, food processing, chemicals, or oil & gas.

- Product Range: Select a supplier that offers a comprehensive portfolio of float-level switches, including specialty models for unique requirements.

- Customization Options: If your application demands special materials, sizes, or certifications, ensure the supplier can deliver custom-engineered solutions.

- Technical Support: Choose partners who provide pre-sales engineering, installation guidance, and after-sales support.

- Certifications & Compliance: Verify that products meet relevant standards (e.g., UL, ATEX, FDA, NSF, CE) for quality and safety.

- Customer Reviews & Case Studies: Research testimonials and real-world examples of successful installations.

To ensure you have the most positive outcome when purchasing float level switches from a float level switch supplier, it is important to compare several companies using our directory of float level switch suppliers. Each float level switch supplier has a business profile page highlighting their areas of experience and capabilities, and a contact form to directly communicate with the supplier for more information or request a quote. Review each float level switch business using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple float level switch companies with the same form.

Ready to request pricing or technical data? Contact top float-level switch manufacturers and suppliers now, or request a custom quote for your unique application.

Frequently Asked Questions About Float Level Switches

- What is the difference between a float-level switch and a continuous level sensor?

Float-level switches provide point-level detection (e.g., full or empty), triggering an action at set points, while continuous level sensors measure the exact level throughout the tank or vessel. - Can float-level switches be used with viscous or dirty liquids?

Yes, many float switches are designed for use with viscous, dirty, or slurry-type media. Selecting the right float design and material is crucial for reliable performance in these applications. - How long do float-level switches last?

High-quality float-level switches can last for many years, with some models rated for millions of cycles. Proper selection, installation, and maintenance further extend service life. - Are float-level switches safe for hazardous locations?

Explosion-proof and intrinsically safe models are available for installation in hazardous (classified) environments, such as chemical plants and fuel storage facilities. - How do I maintain and troubleshoot float-level switches?

Regular inspection, cleaning, and functional testing ensure optimal performance. Refer to the manufacturer’s guidelines for specific maintenance procedures.

Still have questions or need expert advice? Connect with a float-level switch specialist for personalized recommendations and technical support.

Summary: Why Choose Float Level Switches for Liquid Level Control?

Float-level switches remain a cornerstone of liquid level control technology. Their simplicity, durability, and adaptability make them the preferred choice for diverse industries needing reliable point-level detection and automation. Whether you require basic pump control, critical process alarms, or integrated smart system feedback, float-level switches deliver proven performance at a competitive price.

Discover the advantages of float-level switches for your next project. Explore top-rated products, compare suppliers, and request a quote today to start optimizing your liquid handling operations with confidence.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services