Typically, the materials need to remain within the certain range for safety purposes, or because the process depends on having a very specific amount of the material. In addition, level control switches can be used for materials such as liquids, slurries, solids and sludge. Read More…

Sierra`s Innova-Switch™ electronic instruments and devices represent the state-of-the-art in gaseous and liquid flow switching or liquid level control.

At Ryan Herco Flow Solutions, we dedicate ourselves to providing advanced fluid handling products and engineered solutions that meet the demands of a wide range of industries. Our focus is on delivering dependable components and systems that support process efficiency, safety, and reliability.

SOR® level switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. All float level switches are individually built with strict attention to detail to meet the exact specifications of your process. Available as float level switches and displacer level switches, our product offering provides superior...

More Level Control Switch Manufacturers

Level control switches can be essential components in many applications and are used in a wide range of industries, including industrial, for use in manufacturing and processing applications; marine, for use in control of shipboard vessel liquid levels; commercial, for use in applications such as in office buildings, restaurants and more; residential, for use in water level control applications for houses, condominiums and multi-storied apartment buildings; and appliance, for use in water level control in dishwashers, clothes washers and more.

Additionally, level control switches can be used in industries such as automotive, defense contracting, wastewater, agriculture, chemical processing and petroleum. Although there are many domestic applications in which level control switches are utilized, it is in the industrial applications that their high-precision and efficiency become crucial.

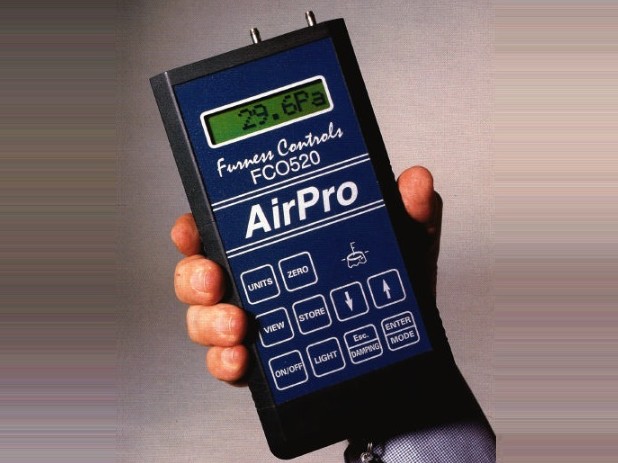

While there are many different ways in which level control switches can function, there are methods that are more commonly used for industrial purposes. Some of these measurement techniques include differential pressure level switches, diaphragm level switches, optical level switches and ultrasonic level sensors. For differential pressure level control, the level of the material is determined from the difference between the two pressures (the pressure at the bottom of the tank compared to the atmospheric pressure) being equal to the height of the material when it is multiplied by the specific gravity of the material.

Diaphragm level control operates in much the same way, determining the level by means of the pressure that is produced at the given depth of a material with a known specific gravity. Optical level switches and ultrasonic level switches, on the other hand, operate in a much different manner than differential pressure and diaphragm level switches.

Optical level switches function by using optical sensors in order to use the light transmittance, reflective or refractive properties of the material being measured to determine its level. Ultrasonic level switches operate by utilizing the energy of ultrasonic acoustic waves, which are sound waves that have frequencies above the normal audible range. They operate by bouncing ultrasonic signals off of materials. The time it takes for the signal to bounce back to the switch indicates the level of the material.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services