Level switches and level sensors are important tools because they provide information about quantities, pressurization, flow and other details about the state of liquid storage and transmission equipment. Read More…

Sierra`s Innova-Switch™ electronic instruments and devices represent the state-of-the-art in gaseous and liquid flow switching or liquid level control.

At Ryan Herco Flow Solutions, we dedicate ourselves to providing advanced fluid handling products and engineered solutions that meet the demands of a wide range of industries. Our focus is on delivering dependable components and systems that support process efficiency, safety, and reliability.

SOR® level switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. All float level switches are individually built with strict attention to detail to meet the exact specifications of your process. Available as float level switches and displacer level switches, our product offering provides superior...

More Liquid Level Switch Manufacturers

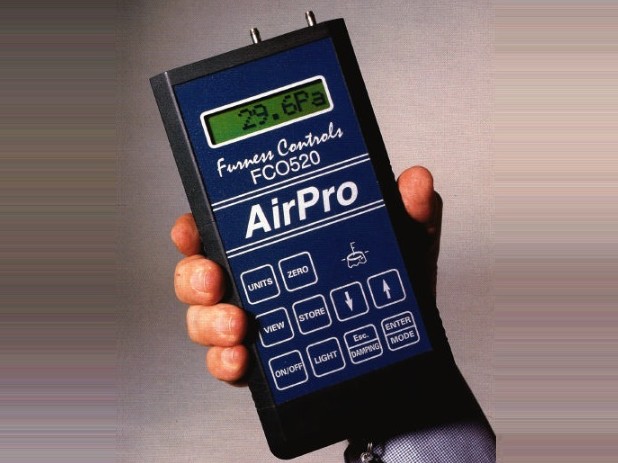

Liquid level switches are useful in many contexts. In fuel storage tanks, for example, tank level indicators can be used to prevent the tank from becoming overfilled during a refilling process. These measurement technologies may include sensors using differential pressure sensing, optical sensing and control, sonic or radar, microwave and pressure-sensing membranes. These switches and their sensors can, if necessary, be finely tuned to measure extremely minute changes in liquid levels.

Liquid levels are measured by the activating or deactivating of a reed switch, relay or a solid-state switch. When the switch's circuit is completed or broken, the signal sent from the switch can be relayed to open or closed valves, operate pumps and initiate other processes. Simple optical sensors, for example, involve the use of LED systems. An LED is used to shine an infrared light through a tank. If the light beam is interrupted, a signal is sent to control equipment indicating levels.

Liquid level switches can be constructed from a variety of materials, including bronze, plastic, PVC, stainless steel and many other materials. They may also be constructed to withstand high temperatures and pressures, and PTFE switches are available for use in high-purity applications. Liquid level switches have a variety of applications including flow line monitoring, household appliances such as heaters and furnaces, automotive, and control technology.

There are many different liquid level switch configurations. The simplest liquid level switch variety is the float level switch, which involves a hollow buoy attached to indicating circuits. When the enclosure in which the level switch is installed is empty, the buoy hangs toward the bottom of the enclosure because of gravity. When the enclosure is sufficiently filled, the rising liquid line causes the buoy to rise. If the buoy rises enough, the circuit in the indicator will close. A signal is then sent from the indicator to gauges or control equipment. Most other liquid level switch varieties are a variation on that design.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services