Mechanical level switches are distinct from non-mechanical utilities like ultrasonic level sensors, optical level switches and capacitance level sensors in that they are always meant to make direct, physical contact with the materials they are used to measure. There are many different mechanical level switch varieties. For example, float level switches, which are used primarily to measure liquid levels in storage enclosures, involve buoyant bulbs that raise and lower based on material levels. Read More…

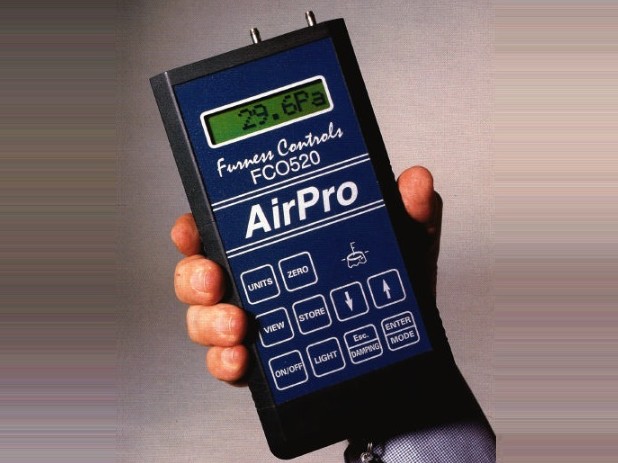

Sierra`s Innova-Switch™ electronic instruments and devices represent the state-of-the-art in gaseous and liquid flow switching or liquid level control.

At Ryan Herco Flow Solutions, we dedicate ourselves to providing advanced fluid handling products and engineered solutions that meet the demands of a wide range of industries. Our focus is on delivering dependable components and systems that support process efficiency, safety, and reliability.

SOR® level switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. All float level switches are individually built with strict attention to detail to meet the exact specifications of your process. Available as float level switches and displacer level switches, our product offering provides superior...

More Mechanical Level Switch Manufacturers

Paddle or rotary level switches transmit information about material levels when their rotation is interrupted by contact with the materials they measure. Such systems are simple, accurate tools that can be used in all kinds of contexts. Float level switches are widely used in wastewater treatment plants, agricultural settings, in fuel and other chemical storage systems in many other settings. Rotary and paddle level switches are employed in grain silos, road salt storage systems and in many other contexts in which bulk granular solids are stored. Displacer level switches are also mechanical, and they can be applied in a wide range of contexts.

All level control utilities, mechanical and non-mechanical, can be used for level sensing or for both sensing and control. The simplest level sensors only detect and report levels in an enclosure or transmission system. For example, a simple float level switch may involve only a moving part that changes position as it comes into contact with rising materials; if sufficiently displaced, the circuit in the switch closes, indicating that the material level has reached a certain point.

The same can be true of other simple mechanical level switches like paddle and rotary switches. More complicated systems involve both reporting equipment and control equipment. Once a level is measured in such systems, a signal can be sent to control equipment that prevents the level from rising further. Such systems are very valuable in liquid enclosures, because they can prevent overfilling or other problems. Mechanical level switches offer a few advantages over non-mechanical switches.

In terms of design and construction, they are often much simpler, which means that they can be less expensive and easier to replace. That said, non-mechanical level switches, which are usually not intended to come into direct contact with the materials they measure, are less likely to become damaged or degraded by the materials they measure precisely because they are isolated from them.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services