Chambered level switches are a type of level sensor that helps measure the amount of liquid inside a container. The switches can also alert the factory workers to when the levels in the containers are too high or too low, preventing dangerous accidents in the factory. Because of their effective use and safety additions, chambered level switches have a variety of applications in all kinds of manufacturing industries. Below you can find a list of applications for standard chamber level switches:

Food preparation: The enclosed nature of a chambered switch makes it ideal for use in the food preparation industry. Safety and cleanliness is extremely important when working with food, and chambered switches keep the components of the switch from ever touching the food. A chambered switch can identify the level of a liquid in a container, such as liquid sugar, melted candies and ingredients, milk and other dairy products, and other food-related materials.

Automotive industry: Chamber level switches are used in the automotive industry to identify the level of transmission fluid and fuel inside a vehicle. The chamber around the switch keeps the somewhat corrosive materials from damaging the switches and distorting the reading. Accuracy is important in the vehicle industry, which is why chambered switches are so important.

Chemical processing: Any time dangerous chemicals are in play, it is necessary to have additional protection and coatings for all materials involved near the chemicals. A chamber around a sensor can protect the delicate mechanisms inside the switch from toxic or corrosive chemicals.

Metal forging: Even the metal industry sometimes uses level switches to monitor the level of liquids in the metal forming or forging process. The sensors are often used to ensure the level of liquid metal or chemical additives do not get too high or low. Chambered switches are essential for keeping the switch components safe from molten metal and harsh chemicals that could damage the internal mechanisms of the switches.

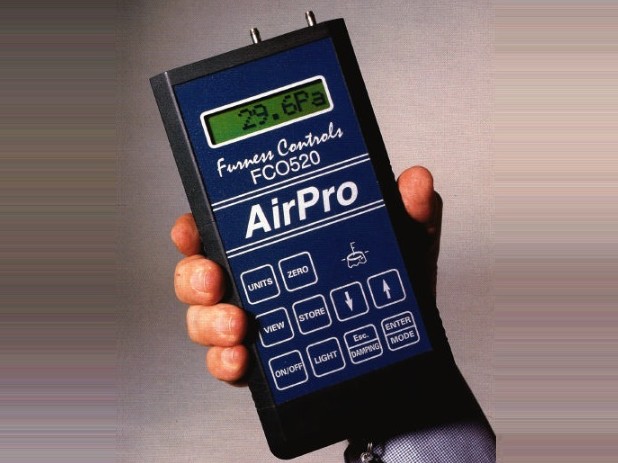

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services