Usually metallic, tanks can be a fairly broad category including 30 gallon and 55 gallon drums as well as most other types of large containers such as hoppers or bins. Read More…

Sierra`s Innova-Switch™ electronic instruments and devices represent the state-of-the-art in gaseous and liquid flow switching or liquid level control.

At Ryan Herco Flow Solutions, we dedicate ourselves to providing advanced fluid handling products and engineered solutions that meet the demands of a wide range of industries. Our focus is on delivering dependable components and systems that support process efficiency, safety, and reliability.

SOR® level switches have earned a long-time reputation for their high quality, rugged construction and reliable performance under the most demanding applications. All float level switches are individually built with strict attention to detail to meet the exact specifications of your process. Available as float level switches and displacer level switches, our product offering provides superior...

More Tank Level Indicator Manufacturers

Tank level indicators are fairly versatile types of level switches and can be used in diverse applications and industries, including petroleum, for level control of oil and gas in refineries; industrial manufacturing, for measurement of the levels of various processing media; chemical processing, for preventative level control of potentially hazardous materials; marine, used in the measurement of marine vessel fluid levels; and residential, for a variety of level indicating applications.

Tank level indicators can be used not only in above ground tanks, such as overhead tanks or grounded tanks, but they can also be used for level control in underground tanks as well. Due to the diversity of the capabilities of tank level indicators, additional industries that utilize them include defense contracting, commercial, private sector aircraft manufacturing, agriculture and wastewater treatment.

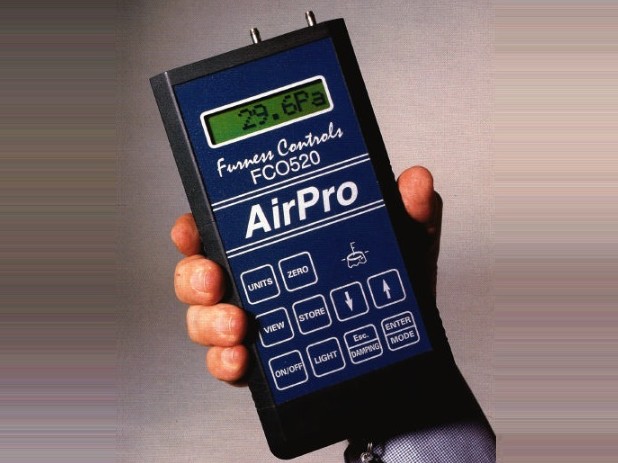

Tank level indicators function mainly to measure the level of various materials based on the principle of differential pressure. This means that the level indicator is able to determine the level of the material due to the difference between the two pressures (the pressure at the bottom of the tank compared to the atmospheric pressure) being equal to the height of the material when it is multiplied by the specific gravity of the material.

As a result, as long as the gravity of the material (or the density) remains the same, then the tank level indicator will be able to accurately measure the level of the material. When level measurement is based upon this principle, it is also commonly referred to as hydrostatic tank gauging (HTG). Floating level indicators are often a popular form of tank level indicators, and continuous level floats are one of the most accurate ways of measurement control in tanks.

A continuous level float functions by means a sensors (which can range anywhere from two to 25 ft in length) is inserted at the top of the tank through either a flanged, welded or screwed connection. The accuracy of level measurement using this type of device is approximately up to .02 in. and as a result is used in many applications requiring high precision in measurement.

Flow Meters

Flow Meters Leak Detectors

Leak Detectors Level Switches

Level Switches Pressure Gauges

Pressure Gauges Pressure Switches

Pressure Switches Pressure Transducers

Pressure Transducers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services